Many customers don’t know how to choose a compatible LED light strip width for their LED profiles. As decorative and heat dissipating components of LED light strips, width compatibility between LED profiles is crucial. This article briefly explains why compatibility between LED light strips and LED profiles is crucial. It also explains how matching width, mounting method, and heat dissipation performance affect lighting performance and lifespan.

Understanding LED Strips and LED Profiles

We need a detailed understanding of the definitions of LED light strips and LED profiles to help us make better choices.

LED Strip Lights

LED strips, also known as flexible LED light strips, are narrow circuit boards with LED chips mounted on them, emitting light along their length. They are flexible, cuttable, and easy to install, making them a best-selling product in both residential and commercial lighting.

Common types of LED light strips include:

- SMD (Surface Mount Diode): The most widely used type, and the traditional LED light strip. Different brightness levels and color options are available depending on the LED chip size (e.g., 2835, 5050, 3528).

- COB (Chip-on-Board): This is a newer type of LED light strip. It uses a dense array of LEDs on a single circuit board to produce continuous, spotless lighting output, ideal for uniform illumination.

LED Aluminum Profile

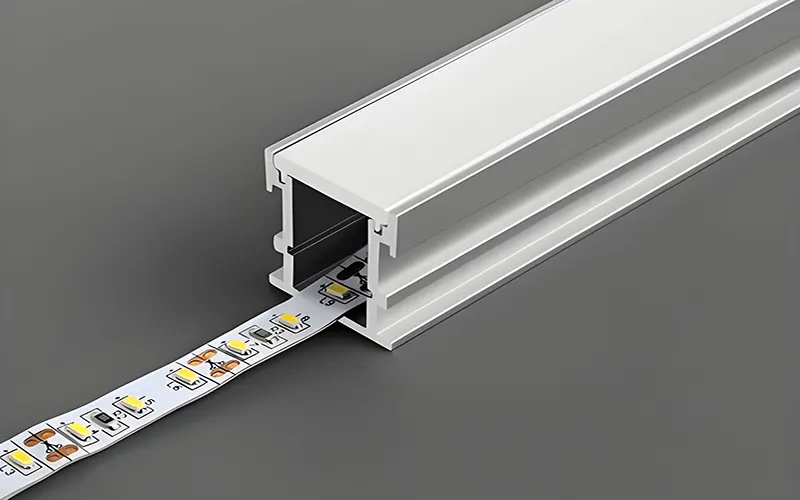

LED profiles, also known as aluminum channels or extruded profiles, are protective housings used to secure and mount LED light strips. They are typically made of anodized aluminum and come with a diffuser (clear, frosted, or milky white) and a cover to soften the light output. LED profiles not only improve the appearance of the installation but also enhance heat dissipation and extend the lifespan of the LED light strip. Pls read Understanding LED Profile Dimensions

Common LED profile types include:

- Surface Mount Profiles: Installed directly on walls, ceilings, or furniture for general lighting.

- Recessed Profiles: Embedded in walls, ceilings, or floors for a seamless, modern look.

- Corner Profiles: Designed for 45-degree lighting angles in corners or under cabinets.

- Ceiling Mount Profiles: Suspended from the ceiling for use with mounting hardware.

How do LED Strips and LED Profiles Work together?

The LED light strip provides the light source, while the LED profile provides support and protection. Using them together creates a clean, professional lighting effect and optimizes performance. The aluminum housing of the profile helps dissipate heat, ensuring the LED chips maintain stable brightness and a longer lifespan.

The diffuser softens the light, eliminates glare, and produces a continuous lighting effect. It transforms a simple LED light strip into an elegant architectural lighting element.

Why Does the Width of an LED Strip Determine the Size and Compatibility of Available LED Aluminum Channel?

LED strip widths are typically measured in millimeters (mm), such as 5mm, 8-12mm, and even exceeding 20mm.

However, the width of the inner groove in each LED aluminum profile is fixed. For example, small grooves are 6-8mm wide, suitable only for narrow LED strips. High-power grooves are 15-20mm wide, used for double-row LED strips.

Therefore, the strip width must match the profile’s inner groove width. If the strip is too wide, it won’t fit properly or will damage the light guide; if it’s too narrow, the strip will easily slip, have poor heat dissipation, or affect light uniformity.

Installation Tips for LED Strip and LED Profile

When selecting LED strips and LED profiles, careful consideration of their dimensions is crucial. Appropriate dimensions are essential; strips that are too wide or too narrow will hinder installation.

Pre-installation Preparation and Cutting Precautions

Before installation, be sure to measure the length of the LED strip and the profile, and plan according to the dimensions of the installation area. When cutting the LED strip, always cut at the cut line indicated by the supplier; otherwise, it may cause the LEDs to not light up or the circuit to short-circuit.

In addition, it is recommended to conduct a test lighting before installation to confirm that the color, brightness, and control effect are normal before fixing. For LED strips that need to be spliced, use dedicated connectors or soldering to ensure good electrical contact.

Proper Fixing of LED Strips and Wiring

When fixing LED strips, choose a flat, dry, dust-free surface. Ideally, LED strips should have self-adhesive backing for long-term stability. We can use mounting clips for fixing.

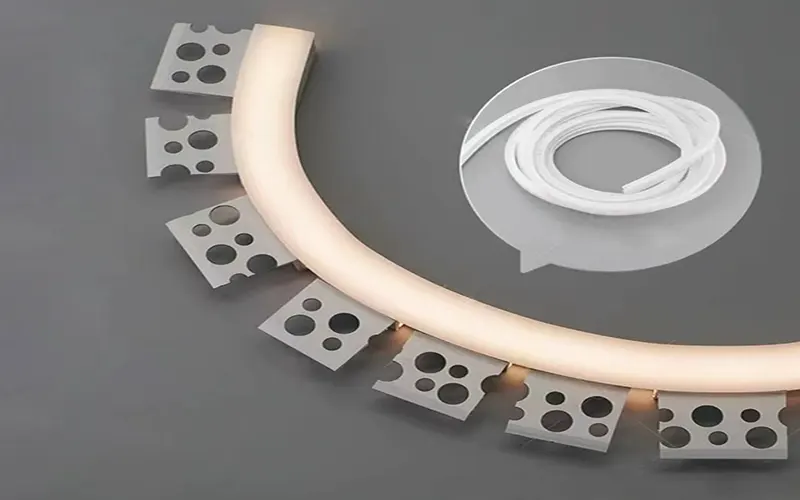

When routing wiring, pay attention to the power supply direction and the controller location to avoid voltage drop problems caused by excessively long cables. For corners or curved areas, choose flexible profiles or bendable LED strips to ensure uniform and continuous light.

Using End Caps, Mounting Clips, and Diffusers

End caps effectively prevent dust and moisture from entering the profile; these are usually included. They also improve the overall aesthetic appearance. Mounting clips facilitate quick and easy installation and removal, making future maintenance and LED strip replacement convenient.

Diffusers soften the light, reduce glare, and conceal the pixelation of the LED chips. For a softer, linear light effect, a high-density COB LED strip paired with a milky white diffuser can be used.

How to Choose the Right LED Profile and LED Strip?

Choosing LED profiles involves considering not only appearance and function, but also ensuring compatibility with the width of the LED strip you intend to use. Our company offers LED profiles in various sizes suitable for LED strips of different widths.

We also provide end caps and various diffusers, equipped with adjustable clips, ensuring easy installation and achieving your ideal lighting effect.