LED light extrusions give LED light strips a compact form factor and beautiful design. They provide functionality and reliability for both indoor and outdoor lighting applications.

Due to the different sizes and mounting methods of LED light extrusion, you can find LED light extrusion in a variety of lighting applications. This comprehensive guide delves into the world of LED light extrusion, exploring its benefits, applications, mounting methods, and more.

What is a LED Light Extrusion?

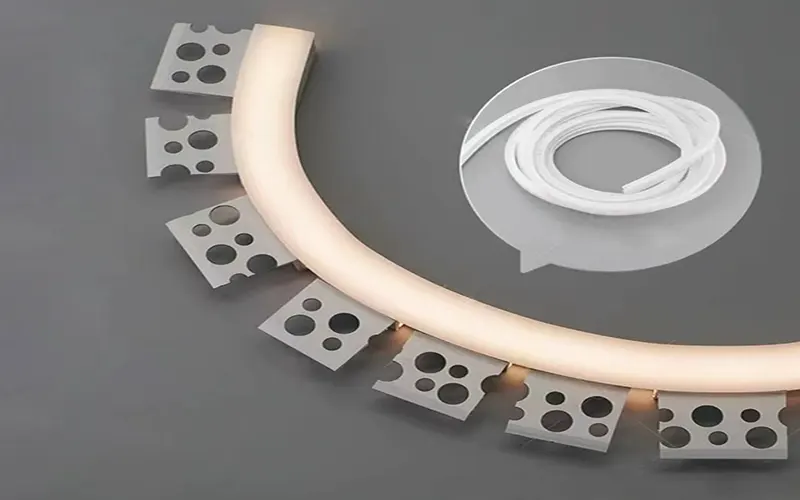

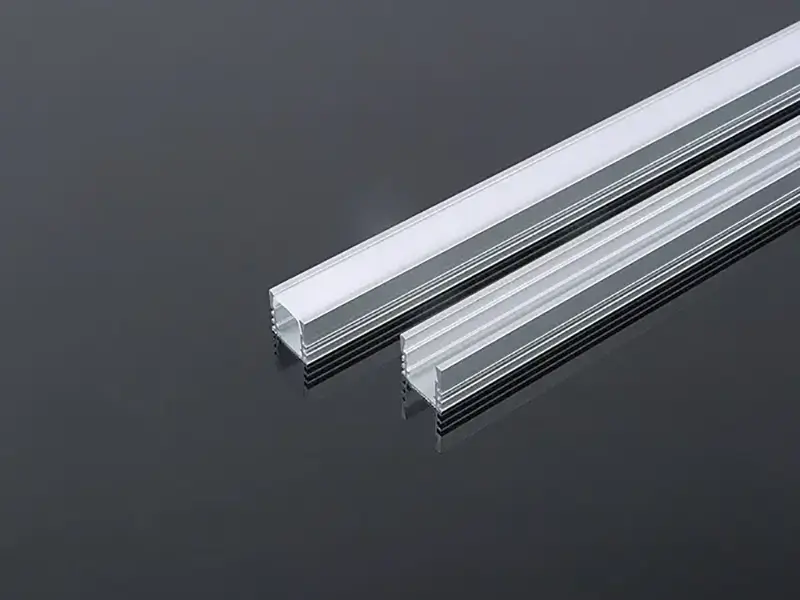

At its core, an LED Light Extrusions is an LED aluminum profile designed to house LED strip lights. They will provide structural support while enhancing light diffusion and aesthetics.

These LED extrusions come in various shapes and sizes, catering to different lighting requirements and design preferences. By encapsulating LED strips within durable aluminum channels, these LED extrusions ensure efficient heat dissipation and prolonged LED lifespan.

What are the Benefits of Using LED Light Extrusions?

Ensure Uniform Lighting

Although LED light strips are sufficient to provide sufficient lighting by themselves, sometimes their light distribution is often uneven and unbalanced. If you use LED light strips for ambient or accent lighting, it will have a great impact if its light is uneven.

At this time, the LED light strip needs to be equipped with accessories such as LED light extrusions and covers. This cover can also be used as a diffuser to focus and diffuse the light from the LED light strip. Make its bright lighting effect better and more harmonious.

More Flexibility

LED strip lights are long, thin strips of light that are very inconvenient to use. They are not easy to install because they have no accessories. You may be able to use tape to fix them in a specific position, but it is just simple lighting and cannot be used as decorative lighting.

By using LED light extrusions, you have more freedom to choose how, where and in what way to place the LED lights. For example, fix the LED light strip to the ceiling, or press it to the ground. This freedom provides lighting diversity when designing the lighting system in an architectural.

Provides Protection

LED strips are durable, but if they are not IP20 waterproof, they are equivalent to bare boards. However, LED strip lights are often very fragile and can be easily broken, crushed, or otherwise damaged.

LED light extrusions protect LED strips from physical damage, whether it is wear or tear. This is an excellent way to ensure the reliability and durability of LED strip lighting installations. At the same time, it can also assist in the heat dissipation of LED strips, extending the life of the light.

Linear Appearance

LED lighting strips generally provide excellent lighting, but without the LED profiles, users can see that it has a shape that is not very aesthetically pleasing.

Aluminum extrusions are a great choice for LED light strips. They are available in a variety of types and colors to perfectly blend into a variety of indoor and outdoor designs. Again, they can make your lighting installation look professional, and the LED light strips will not be clearly visible when assembled together.

Where to Use LED Light Extrusions?

LED Light Extrusions are incredibly versatile and can be used in various applications, including:

- Architectural Lighting: Enhance architectural features and create visually stunning effects with LED Light Extrusions integrated into building facades, ceilings, and walls.

- Interior Design: Illuminate residential interiors with LED Profile Light installed in kitchen cabinets, shelves, staircases, and furniture to add ambiance and functionality.

- Retail Displays: Highlight products and create captivating displays in retail environments using LED Light Extrusions to draw attention and enhance merchandise visibility.

- Hospitality: Create inviting atmospheres in hotels, restaurants, and bars with LED Profile Light incorporated into decorative elements, signage, and accent lighting.

- Commercial Spaces: Illuminate offices, conference rooms, and workstations with LED Light Extrusions to improve productivity, comfort, and energy efficiency.

How to Install LED Light Extrusions?

Preparation: Measure the installation area and ensure it is clean and free from debris. Gather all necessary tools and materials, including LED strips, aluminum extrusions, end caps, and mounting accessories.

Cutting and Assembly: Cut the LED strips and aluminum profiles to the desired lengths using a saw or specialized cutting tool. Assemble the components, ensuring a snug fit and proper alignment.

Mounting: Secure the assembled LED Extrusions in place using adhesive tape, mounting brackets, or screws, depending on the installation surface and requirements.

Wiring: Connect the LED strips to a suitable power source and controller, following manufacturer guidelines and wiring diagrams. Test the installation to ensure proper functionality.

Finishing Touches: Install end caps and diffusers to provide a clean finish and enhance light diffusion. Conceal wiring and connectors for a professional-looking installation.

How to Find LED Light Extrusions Manufacturers?

Are you looking for an experienced LED profile manufacturer? With 12 years of experience in LED light extrusions, ESLEDPROFILE is your best partner for LED housing aluminum extrusions. As a trusted LED extrusion procurement service provider, we guarantee quality and provide world-class products and services to our customers.

Contact us today to discuss your LED extrusion project with us.