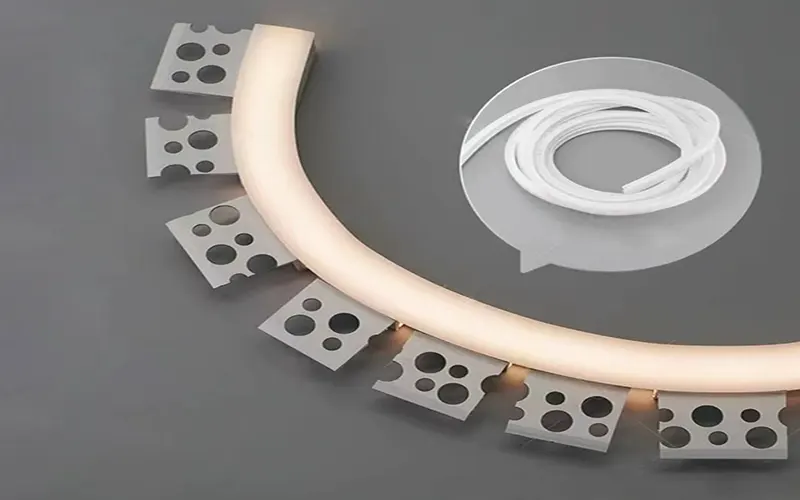

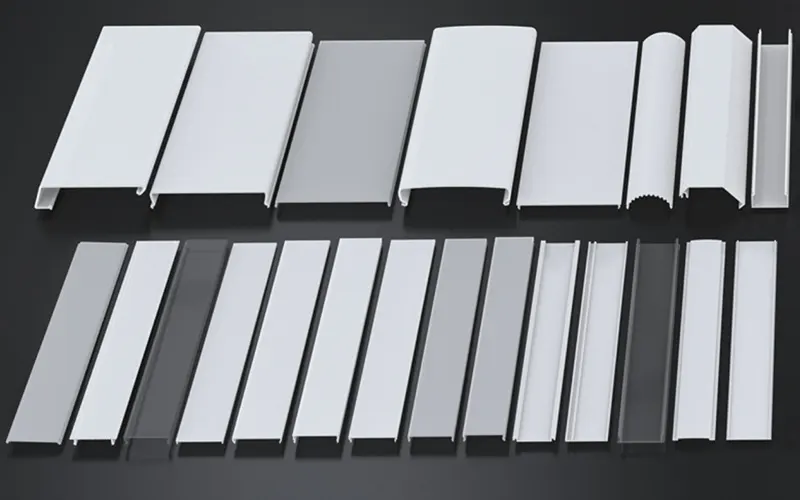

LED diffusers and LED profiles are integrated, housing LED strips. They provide protection and heat dissipation for the LED lights. In particular, LED strip diffusers distribute light evenly. However, over time, some users may find their LED diffusers begin to fade or yellow, affecting the overall appearance and quality of the lighting. Next, we’ll understand the causes of fading and yellowing in LED strip light diffuser cover and how to prevent it, which is crucial for maintaining the lifespan and performance of your LED lighting system.

What Causes LED Strip Light Diffuser Cover to Fade and Yellow?

When LED light diffusers fade, yellow, and lose transparency, it’s not caused by a single factor. Several factors can contribute to this: material aging + environmental influences + thermal stress + chemical contamination + product quality differences, among others, resulting in a long-term cumulative effect. Below is a systematic analysis of the most critical aspects.

Ultraviolet (UV) Exposure

Ultraviolet (UV) radiation is the leading cause of aging and yellowing in LED diffusers. Therefore, avoid environments near windows, skylights, and glass curtain walls.

Most diffusers use PC (polycarbonate) or PMMA (acrylic) materials. Under prolonged UV exposure, these polymers experience molecular chain breakage, accelerated surface oxidation, and a gradual decrease in transparency, causing the color to change from milky white to pale yellow or even dark yellow.

Heat Accumulation

While LEDs are more energy-efficient than traditional light sources, they still generate heat. We must also consider factors such as high LED power, overly tight diffuser sealing, and poor ventilation. These can all cause heat to accumulate inside the diffuser over a long period.

If the LED strip diffuser is exposed to temperatures above 60–90°C for extended periods, the polymer structure undergoes thermal degradation, causing the color to gradually shift towards a yellowish hue.

Chemical Reactions

In practical use, many users overlook the long-term effects of airborne chemical pollutants on diffusers. Some chemical pollutants, such as sulfides and nitrogen oxides in the air, can have an impact.

These substances can react with the diffuser surface to cause oxidation, leading to fogging and localized yellowing of the LED light strip diffuser cover.

Inferior Raw Materials

The quality of materials used in diffusers on the market varies greatly. They may look similar at first glance, but the differences become apparent over time.

If the LED light strip diffuser is made from poor-quality raw materials, the initial color will not be pure white, the surface will appear dull, and the light transmittance will be low.

Improper Installation Environment

LED profiles need to be installed in dry, well-ventilated locations. Yellowing will be significantly accelerated in the following environments: bathrooms, swimming pools, and underground parking lots (where humidity is consistently high).

This is because moisture will spread to the diffuser surface and condense, which over time accelerates oxidation and chemical degradation.

How Does UV Radiation Affect LED Strip Diffusers?

UV radiation is one of the main causes of yellowing in LED diffusers, especially in areas with direct sunlight. Over time, UV radiation causes photodegradation, breaking the chemical bonds in the plastic material and causing it to yellow.

- Indoor vs. Outdoor Installation: Indoor diffusers are generally exposed to less UV radiation than outdoor diffusers. It is recommended to use UV-resistant materials, especially in sunny areas.

- For installation in high-UV environments: To minimize UV damage, use UV-resistant diffusers specifically designed for outdoor or high-intensity environments.

Why Does Heat Cause LED Light Strip Diffuser Cover to Yellow?

Many are unaware that overheating can significantly impact the lifespan and appearance of LED diffusers. While LEDs have relatively weak heat dissipation capabilities, they still generate some heat.

Without proper ventilation or heat dissipation, surrounding materials, including the diffuser, may age. This is especially important if the diffuser is installed in a well-ventilated location, while also ensuring the LED strip power is not too high.

- Thermal Management: To prevent heat buildup, ensure your LED lighting system is equipped with sufficient heat sinks or ventilation. This helps dissipate excess heat and reduces the risk of the diffuser yellowing due to overheating.

- High-Power LEDs: While high-power LEDs offer higher brightness, they tend to generate more heat. When selecting LED strips, it’s crucial to strike a balance between brightness and heat dissipation to prevent yellowing of the diffuser.

How Do the Materials Used in LED Light Strip Diffuser Cover Affect Fading and Yellowing?

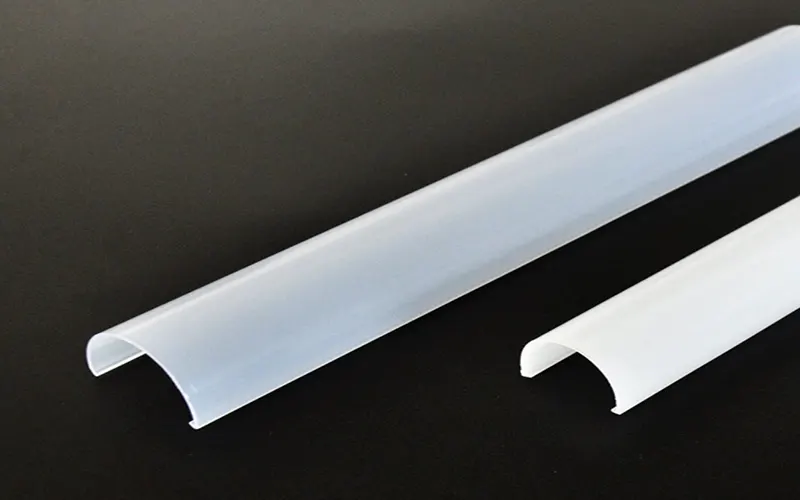

The quality of materials used in LED light strip diffusers plays a crucial role in their lifespan. High-quality polycarbonate or acrylic diffusers are more resistant to fading and yellowing than cheaper plastic diffusers.

Low-cost diffusers may yellow more easily because they are made from materials with weaker resistance to UV rays, heat, and environmental factors.

- Choosing the Right Materials: Polycarbonate diffusers are known for their strength and resistance to UV rays and heat. Acrylic diffusers also offer good clarity and durability, but may yellow more easily under extreme conditions.

- The Importance of Quality: Investing in high-quality LED light strips and diffusers is essential for long-term performance. While they may initially cost more, they are less prone to aging and maintain their aesthetic appeal for longer.

How Do Chemical Reactions Affect the LED Strip Lights Diffuser Cover?

LED diffuser strips can also fade or yellow if they come into contact with certain chemicals. This is especially common with plastic materials exposed to strong cleaners or airborne chemicals.

For example, some cleaners contain ammonia or alcohol, which can react with the diffuser material, causing yellowing. Keep these chemicals away from the LED diffuser.

- Proper Cleaning Method: When cleaning LED diffuser strips, always use a mild, non-abrasive cleaner. Avoid using strong chemicals that accelerate the aging process; instead, choose water-based or mild detergent solutions.

- Air Quality Considerations: In industrial or polluted environments, chemical reactions in the air can cause yellowing. Maintaining good ventilation and using chemically resistant materials can help mitigate this problem.

How to Prevent LED Light Strips Cover from Fading and Yellowing?

Fading and yellowing are common problems with LED strip diffusers, but there are measures we can take to minimize and prevent them.

- Choose a UV-resistant diffuser: If installed outdoors, you should choose diffuser materials specifically designed to resist UV rays.

- Ensure adequate heat dissipation: Proper heat management, including the use of heat sinks and ventilation, can prevent yellowing caused by overheating and extend the diffuser’s lifespan.

- Use high-quality materials: Invest in high-quality LED strip and diffuser materials, such as ESLEDPROFILE’s LED aluminum covers.

- Clean carefully: Use mild cleaning products that do not contain harsh chemicals. Regularly dust and clean the diffuser to prevent dust buildup, which can also cause fading.

When Should I Replace an LED Light Strip Diffuser Cover?

It mainly depends on the condition of the LED light strip diffuser cover. If it’s already affecting the brightness and visibility of the LED strips inside, then the LED diffuser strip will eventually need to be replaced.

UV radiation, high temperatures, and natural wear and tear caused by environmental factors can cause the diffuser strip to fade over time. Here are some signs that a diffuser strip needs replacing:

- Severe yellowing or fading: If yellowing or fading is significant and affects the overall appearance of the lighting, consider replacing the diffuser strip.

- Cracking or warping: The diffuser strip is exposed to excessive heat or UV radiation for extended periods, it may crack or deform.

- Reduced Light Output: If the diffuser strip is affecting the brightness of the LED lights, replacing the diffuser strip can restore its original light quality.

Conclusion

Fading and yellowing of LED light strip diffuser cover are common problems, mainly due to UV exposure, heat buildup, material quality, and chemical reactions. Therefore, choosing high-quality, UV- and heat-resistant materials and maintaining proper cleaning and installation methods can extend the diffuser’s lifespan and maintain the quality of the lighting system. For more high-quality LED profiles and LED strip diffusers, please contact us.