When installing LED strip light profile, lighting users often encounter the problem of uneven light distribution. For example, the light may appear uneven, some areas may be dim, or the light distribution across the entire strip may be inconsistent. This not only affects the lighting effect but also reduces overall lighting efficiency. Let’s analyze the reasons that cause uneven light distribution in LED strip light profile.

Why is My LED Strip Light Profile Uneven?

This phenomenon does indeed occur. However, it’s not just a problem with LED light strips and LED profiles. We can analyze it from the following six aspects. More details, pls read Why Does the LED Strip need the LED Profile?

Improper placement of LED strips

The installation position of LED strips is crucial for uniform light distribution. The specific location of the LED strip installation needs to be planned in advance. For example, if the LED strip is not centered on the profile, or if it is twisted or bent during installation, the light projection direction will be uneven, resulting in uneven brightness.

To ensure uniform light distribution, the strip should be installed as straight as possible and centered on the profile. Additionally, the back of the strip usually has self-adhesive tape; it is recommended to carefully apply it, ensuring a firm and flat finish.

If the strip is installed on an uneven surface, it will also affect the light reflection angle, potentially creating shadows or light spots.

LED strip density affects light uniformity

The density of an LED light strip, specifically the number of LED chips per meter, significantly impacts the uniformity of light output.

Generally, the higher the density of the LED strip mounting profile, the smoother and more continuous the light. This is because high-density strips can reduce the spacing between LED chips, eliminating “gaps” in the light beam. Currently, we generally recommend using COB LED light strips with no light spots.

When purchasing LED light strips, you can choose the appropriate density based on your specific application. For example, if the strip is only used for decorative lighting, a low-density strip may be sufficient. For more information on high-density LED light strips, please contact us.

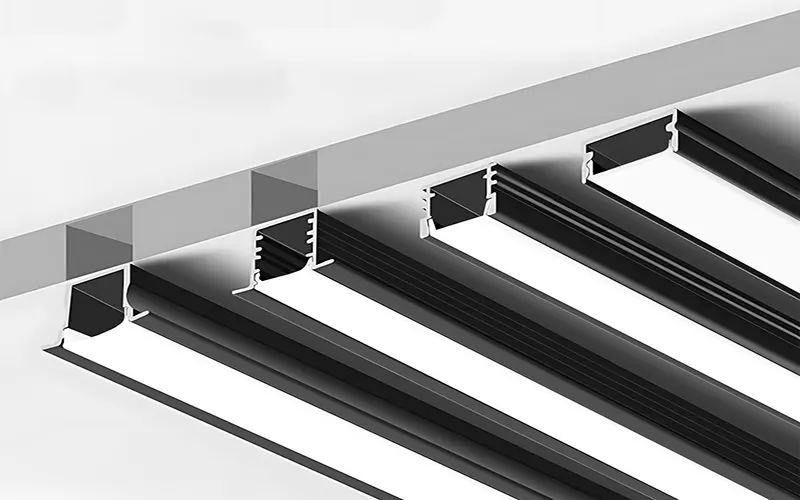

Importance of Diffuser Type Selection

The main function of a diffuser is to help distribute light more evenly and reduce light spots. The light diffusion effect also varies depending on the diffuser’s material and transparency.

Transparent diffusers allow light to pass directly through, resulting in higher brightness but also more noticeable light spots and clearly visible spacing between LEDs. Frosted or milky white diffusers effectively mix light, blending the light emitted by individual LEDs to create a softer, more even lighting effect.

This type of diffuser is particularly suitable for scenarios requiring high light quality, such as background lighting or decorative lighting. If your LED strip’s light is uneven and you are using a transparent diffuser, replacing it with a frosted diffuser may be a simple and effective solution.

LED Strip Light Quality Issues

The quality of LED strip lights does indeed affect the consistency of output light. Some low-quality LED strip lights not only have insufficient brightness and a short lifespan, but also potentially poor uniformity of light output.

Specifically, different LEDs on the same strip may have different brightness or color temperatures, resulting in uneven lighting across the entire strip. With some areas brighter and others darker, affecting the overall visual effect.

To avoid such problems, it is recommended to choose LED strip light brands with guaranteed quality. Although high-quality strip lights are relatively more expensive, they have a longer lifespan. More stable brightness and color temperature, and provide a more uniform and comfortable lighting effect.

Uneven Brightness Due to Power Supply Issues

Power supply issues are a common cause of uneven brightness in LED light strips. LED light strips require a stable power supply to maintain a continuous, uniform current. If the power supply’s rated power is insufficient or its quality is poor, uneven brightness may occur.

When selecting a suitable LED power supply, ensure its power is sufficient to support the entire LED light strip’s operation. If the power supply’s power is too low, the light strip will not perform optimally.

Additionally, pay attention to voltage matching between the power supply and the light strip. For example, a 12V or 24V light strip requires the corresponding voltage. Voltage mismatch between the power supply and the light strip may cause uneven brightness in certain areas of the light strip, or even damage the LED strip.

Poor heat dissipation leads to uneven light distribution

LED strip light profile generate heat during operation, albeit only a small amount, but proper heat dissipation is still important. If this heat cannot be dissipated in time, the light strip will overheat, affecting its brightness and lifespan.

When LED chips operate in high-temperature environments for extended periods, their brightness will gradually decrease. And they may even experience color changes, leading to uneven light distribution within the light strip. Therefore, heat dissipation is also a crucial factor contributing to uneven light distribution in LED strips.

How to Prevent Uneven Lighting in LED Light Strip Profile?

The uneven light distribution issues we analyzed above are not simply a problem with the LED strip itself, but rather caused by improper coordination among four systems: the LED strip, the profile, the power supply, and the heat dissipation. You need to address each of these issues one by one.

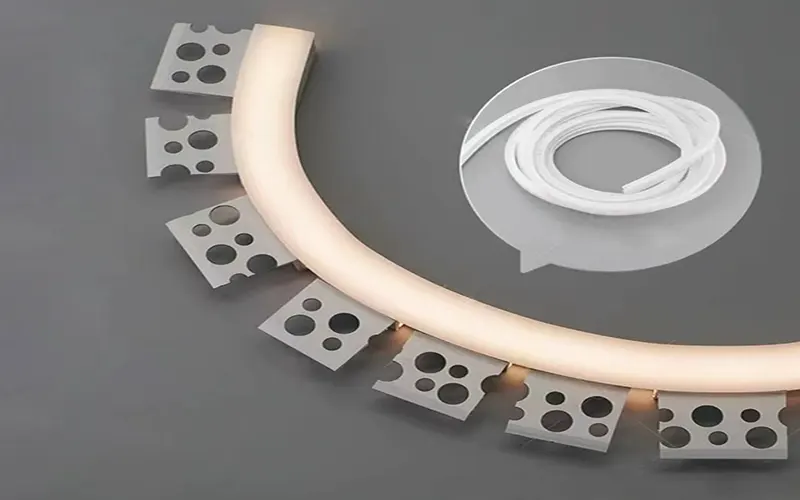

The height of the profile should match the density of the LED strip

Suppose the height of the profile’s inner cavity is too shallow. In that case, the light spot will be obvious, causing the light to be projected directly onto the diffuser, resulting in a “grainy” appearance.

The diffuser must meet both light transmittance and diffusion standards

Choosing the right LED diffuser is crucial; we recommend a milky white, high-atomization diffuser. This ensures a surface free of particles, ripples, and streaks.

High LED density is essential

For any LED strips housed within LED profiles, we recommend high density. At least 240 LEDs or more are ideal; COB LED strips are currently the preferred choice.

Addressing “Dark Sections” at Splicing Locations

The joints between profiles are most prone to appearing partially dark, with a noticeable gap in the middle. Therefore, it’s crucial to ensure that the LED strip doesn’t break off precisely in the middle of the joint; this will minimize its visual impact.

Strictly control the length of single-ended power supply

If the LED strip is connected to too many meters on one side, it will cause inconsistent color temperature. Therefore, the recommended length on one side is 5 meters, and it is best to use double-end power supply or supplemental power in the middle.

Conclusion

Uneven illumination in LED strip light aluminum profile can be caused by a variety of factors, including strip location, density, diffuser type, strip quality, power supply issues, and poor heat dissipation. By carefully inspecting and adjusting each aspect, the uniformity of illumination can be significantly improved. For more LED profiles, please contact me.